Kersten Group

KERSTEN is a leading expert in bending technology and a trusted supplier of precision-curved components and constructions in steel and aluminium. Renowned for its high-quality, precision-engineered solutions, KERSTEN plays a key role in enhancing architectural facades with strength, innovation, and elegance.

Curved aluminium profiles, including curtain walls, window facades and frames for doors and windows. KERSTEN also offers bending and machining services for standard and custom extruded aluminium profiles for facades, balustrades, railings, sliding doors, etc. in various sizes, shapes and finishes

Headquartered in the Netherlands, the company can build on more than sixty years of experience in high-quality aluminium bending technology, with three production facilities in Europe and one in the Middle East. There are also sales offices in Europe and Canada. The company offers advanced bending services, 5-axis machining, heat and surface treatments and assembly services for aluminium profiles - supporting the realization of curved constructions and facades in cutting-edge architectural projects worldwide.

‘Together we turn imaginative ideas into beautiful curved structures around the world.’

Aluminium Bending

KERSTEN’s modern machine parks are equipped with an extensive series of advanced bending machines where aluminium profiles can be bent to almost any desired radius.

Depending on the complexity, dimensions, desired radius and requirements with regard to tolerances and surface quality of the profiles, the correct bending technology is applied.

KERSTEN has mastered the roll bending technology, mandrel bending technology and stretch bending technology.

It is also possible to bend profiles into a 3D shape.

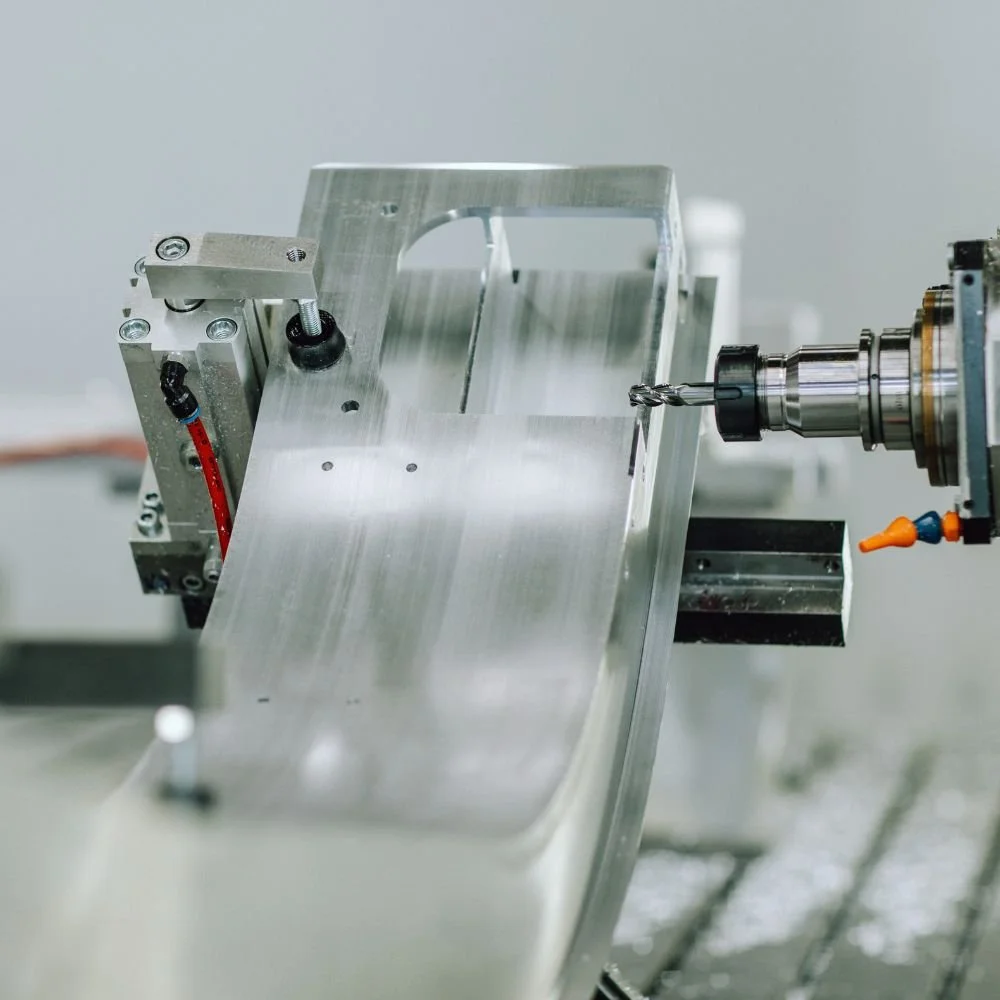

Machining Processes

Machining operations take place after the bending process to ensure the highest level of quality and positioning of the operation.

KERSTEN performs various machining operations, such as double mitre cutting, drilling and milling of bent aluminium profiles. For these operations, 5-axis CNC machining centers specially designed for bent products are used to perform the most complex operations.

Heat Treatments

KERSTEN performs thermal treatments of aluminium products in its own aging furnaces. These treatments include both soft annealing and artificial aging. (from T4 to T6)

Surface Treatments

If required, Kersten provides the bent product with a technical or aesthetic surface treatment.

For decorative applications, KERSTEN offers the following processes, among others

Anodizing

Varnishing

Powder coating